News, Resource Articles

Three Common Types of Screening Projects

One size does not fit all when it comes to undertaking a screening project. Different screening projects require different materials, tools and step-by-step instructions. Three of the mosts common types of screening projects we encounter include replacing a screen, assembling a window screen frame, and screening a porch. Below is a brief overview of each of these screening projects.

Replacing A Screen

Replacing a screen in a window, door or screening system doesn’t have to be a complex job. With the right tools and step-by-step instructions below, you can easily replace your broken or worn out screen.

Materials you will need include:

- new screen roll

- package of spline

Tools you will need include:

- spline tool

- tape

- utility knife or rollerkinfe

Screen Replacement Instructions

Below is a step-by-step guide to replacing a screen in a door, window, or screening system.

#1 Use tape to temporarily hold screen to surface. Be careful not to let the tape cover the spline grooves.

#2 Align the edges of the screen with the frame by placing the screen over the frame. Trim edges if necessary.

#3 Use your spline roller to carefully push the spline and screen into spline grooves, opposite the taped ends of the frame.

#4 Gently remove pieces of tape and continue rolling the remaining screen to the frame.

#5 Trim any excess spline or screen material with the utility knife.

Assembling a Window Screen Frame

If you are looking to add screening to a window, you will first need to assemble the window screen frame. This isn’t an overly complex task, but will require more materials and equipment then simply replacing a screen.

Materials you will need:

- frame pieces

- pull tabs

- tension springs

- corner attachments

- cross brace clips

Tools needed:

- tape measure

- hacksaw

- 45 ° cut miter for 1” frames

Window Screen Frame Instructions

Below is a brief step-by-step guide to assembling your frame for your window screening project.

#1 The screen frame channel is found on most frames. You can measure the height and width of your screen frame channel, or simply use your old screen frame measurements.

#2 If your frame is a 3/4“ frame, don’t forget to square cut your frame pieces to 1-1/2” short of your measurement to make sure the corner pieces will fit. Use the hacksaw for this. Attach the four plastic corners to make a frame.

NOTE: You can buy frame kits for most common sized doors and windows.

If your frame is a 1” screen frame, miter cut the frame pieces at a 45 ° angle. Attach four internal metal corners to make a frame.

#3 To keep the frame in place, insert pull tabs into the bottom horizontal piece. For the top, insert tension springs.

#4 If your frame is taller than 36”, put a cross brace over the middle of the frame for stability. Attach clips to the vertical frame pieces to fasten the crossbar.

Screening a Porch

How to screen a porch is the most common question we get asked in regards to screening projects. The below instructions are for existing porch structures. However, if you do not have an existing porch structure, you can still screen in a porch by using our Screen Wall screening system. More instructions on installing Screen Wall can be found here: https://www.screentight.com/how-to-screen-wall/

Materials you will need:

- porch screening system

- screen

Tools needed:

- spline

- screening tool

- scissors

- hacksaw tin snips or shears

- rubber mallet

- screw gun

- utility knife

Porch Screening Instructions

Below is a brief overview on how to install porch screening systems. Please refer to the below pages for more specific instructions for installing each system

#1 Installing the base: Fit the base over the wood framing, cutting where needed. Base strips usually come butted together and they won’t need notching or mitering. Any cutting of the base or cap will need to be done with a hacksaw, chop saw, sheet metal shears, or anvil style pruning shears.

#2 Use the 1” screws to attach base strip to wood framing. Put a screw in every slot and make the fasteners as snug as they can be without bending the base strip. Leave 1/8” to 1/4” gap wherever the base strips intersect, Leave screws no more than 2 inches from the end of the base strips.

#3 Installing the screen: Using screen that is at least 2 inches wider than the dimensions of the frame, use the spline tool to roll spline and screen into the grooves of the base strip. Roll screen first into the top, then the sides, and lastly the bottom. The Rollerknife™ does the job nicely. A razor knife is great for trimming excess material.

NOTE: Don’t forget to hold the screen taut while putting in the spline to avoid bunching of the screen.

#4 Installing the cap: Snap the cap over the base using the rubber mallet. Fit the inside leg under the base leg before using the rubber mallet when attaching the 3-1/2” cap on the inside length. Only remove the cap from one end to the other, using a screwdriver to pry it up.

Frequently Asked Porch Screening Questions

What size screen roll do you need?

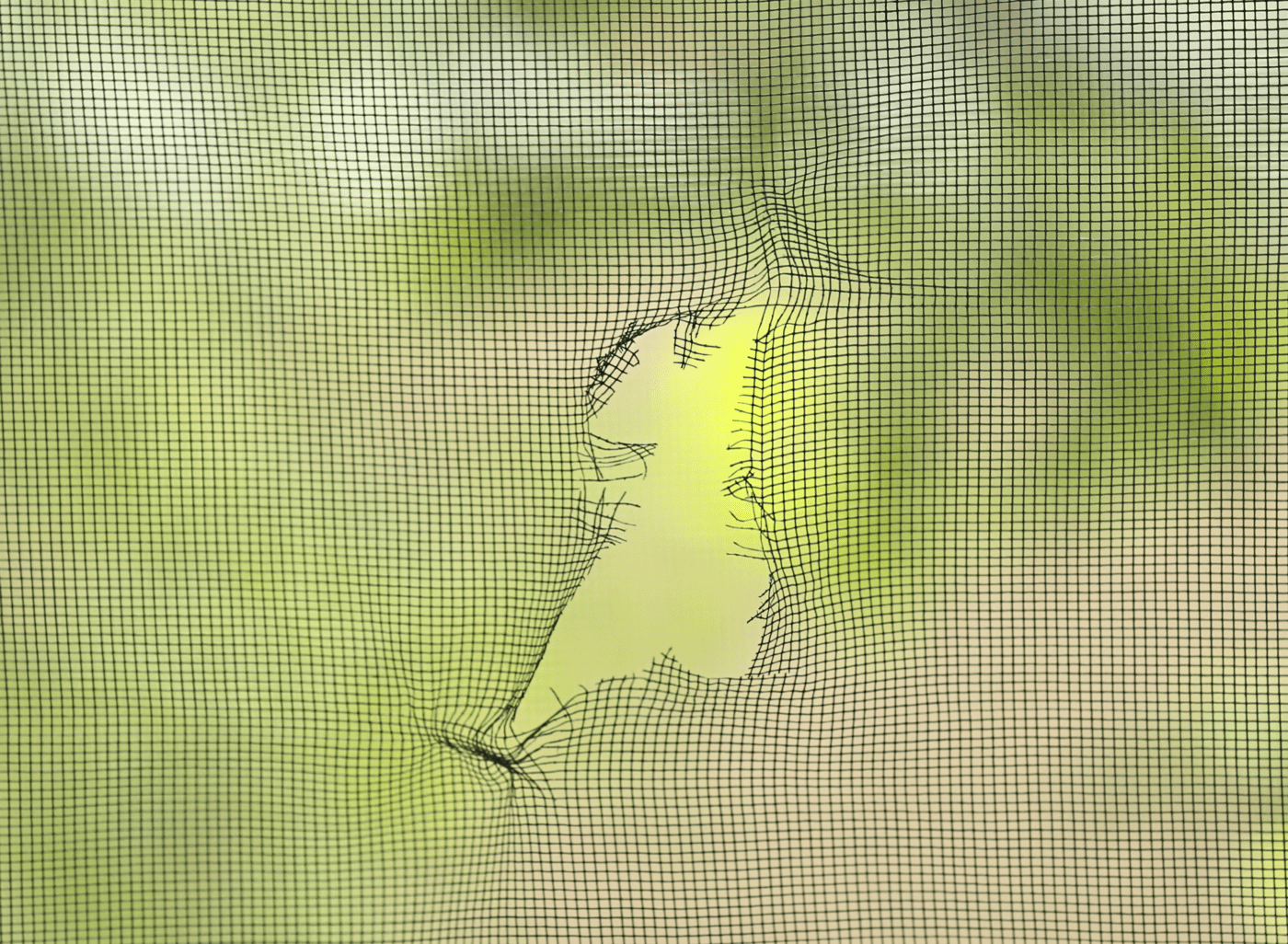

It’s important to get a screen roll that measures 2 inches beyond the opening you’re trying to cover. Choosing a screen roll with the same measurements as the opening you want to cover may lead to holes or buckling of the screen.

What spline size will you need?

Based on what you are screening, you may need to measure the frame groove to find out what spline size you’ll need. For screening systems